Understanding Hydraulic Pumps: The Heart of Modern Machinery

When discussing modern machinery and automation, one cannot overlook the critical role of the hydraulic pump hydraulic pump. These devices are essential components that allow various machines to function effectively. Whether in automotive applications or industrial settings, hydraulic pumps are pivotal for the smooth operation of equipment.

What is a Hydraulic Pump?

A hydraulic pump is a mechanical device designed to convert mechanical energy into hydraulic energy by generating a flow of hydraulic fluid. This process creates pressure that can be utilized to operate hydraulic systems within various applications. The efficiency and performance of hydraulic systems largely depend on the quality and specifications of the hydraulic pumps used.

Types of Hydraulic Pumps

Hydraulic pumps come in various types, each tailored for specific applications and operational needs. Here are the most common kinds of hydraulic pumps:

- Gear Pumps: These are positive displacement pumps that utilize gears to pump fluid by transferring mechanical energy from rotating gears to the hydraulic fluid.

- Vane Pumps: Vane pumps use a rotating vane mechanism to move the hydraulic fluid. They offer good efficiency and are commonly used in applications demanding medium pressures.

- Piston Pumps: These pumps use reciprocating pistons to generate fluid flow. Depending on their construction, piston pumps can handle high pressure and are highly efficient.

- Screw Pumps: Utilizing one or more screws to create a pumping action, these pumps are known for their ability to provide a consistent flow and are often used in industrial applications.

The Importance of Hydraulic Pumps in Various Industries

Hydraulic pumps are ubiquitous in various sectors due to their ability to facilitate power transmission. Below are some industries where hydraulic pumps play a crucial role:

1. Automotive Industry

In the automotive world, hydraulic pumps are vital for steering systems, brake systems, and lifting mechanisms. Power steering systems, for example, rely heavily on hydraulic pumps to provide drivers with easier control of their vehicles.

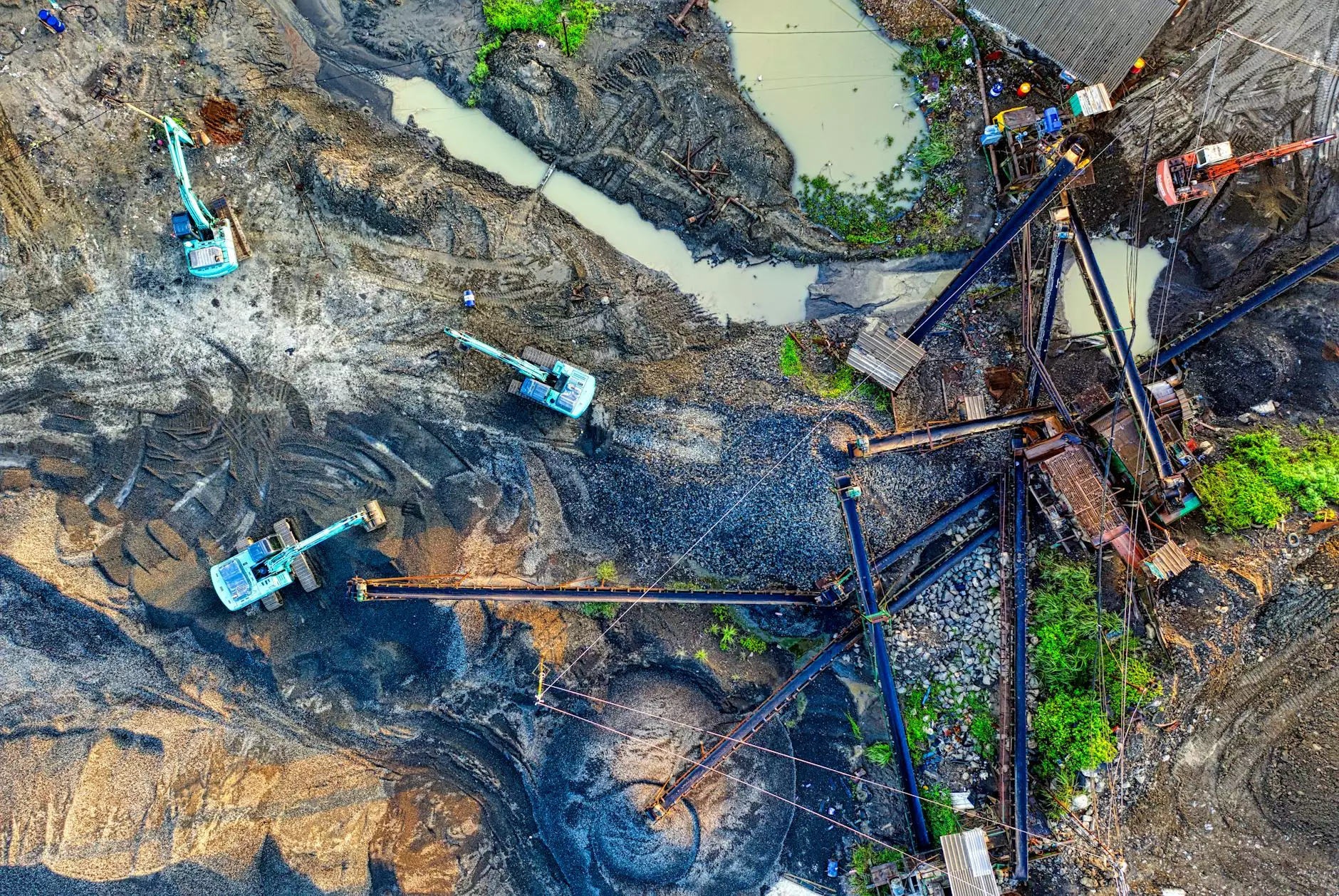

2. Construction Industry

Construction machinery, such as excavators and bulldozers, relies on hydraulic pumps for lifting and digging operations. These machines require significant hydraulic power to function effectively under heavy loads.

3. Aerospace Industry

In aerospace applications, hydraulic systems are essential for controlling various components of an aircraft, including landing gear, flight control systems, and engine components. Hydraulic pumps ensure that these systems operate smoothly and efficiently.

4. Manufacturing Industry

Hydraulic systems are commonly used in manufacturing machinery, including presses, molding machines, and conveyors. The efficiency of hydraulic pumps in these machines improves productivity and output quality.

Key Benefits of Hydraulic Pumps

Using hydraulic pumps in your operations offers numerous advantages:

- High Power Density: Hydraulic systems are capable of producing high amounts of power in a compact form, making them ideal for various applications that require significant force.

- Precision Control: Hydraulic pumps allow for precise control over speed and movement, which is essential in applications where accuracy is crucial.

- Flexibility: Hydraulic systems can be easily adapted for various applications and can also be integrated into existing systems with relative ease.

- Durability: Hydraulic pumps are designed to withstand harsh environments and high-pressure conditions, which contributes to their longevity.

Choosing the Right Hydraulic Pump

When selecting a hydraulic pump, several factors must be considered to ensure optimal performance:

1. Understand Your Application Needs

Identify the specific requirements of your application, including the maximum pressure, flow rate, and the type of hydraulic fluid that will be used. This information will significantly influence your pump choice.

2. Evaluate Pump Type

Select the pump type that best suits your application. Gear pumps might be economical for low-pressure applications, while piston pumps might be necessary for high-pressure environments.

3. Consider Efficiency Ratings

Efficiency is critical in hydraulic systems, as it can influence operational costs. Look for pumps with high efficiency ratings to minimize energy losses.

4. Maintenance Requirements

Understand the maintenance needs of the pump you are considering. Some pumps require more routine servicing than others, which can affect overall operational costs.

Shopping for Hydraulic Pumps at Shop Hydraulic America

At Shop Hydraulic America, we specialize in high-quality hydraulic pumps suited for diverse needs across different industries. Our categories include:

Auto Parts & Supplies

We offer a comprehensive collection of hydraulic pumps specifically designed for automotive applications. Whether you need pumps for power steering or hydraulic brakes, you’ll find the right products that meet industry standards for reliability and performance.

Motorcycle Parts & Supplies

Motorcycles also depend on specialized hydraulic systems. Our range of hydraulic pumps and related parts ensures that motorcycle enthusiasts can maintain and upgrade their rides for optimal performance.

Conclusion

In conclusion, the hydraulic pump hydraulic pump is a crucial component in modern machinery, enabling efficient power transmission across a variety of industries. Understanding the different types of hydraulic pumps and their applications will help you make informed decisions whether you are in the automotive field, construction, aerospace, or manufacturing. Make sure to explore our selection at Shop Hydraulic America to find the best hydraulic solutions tailored to your needs.

Frequently Asked Questions (FAQs)

1. How often should I replace my hydraulic pump?

The lifespan of a hydraulic pump can vary, but regular maintenance is key. Generally, pumps should be inspected every 3 to 6 months and replaced once significant wear is detected or after approximately 1,500 hours of operation.

2. Can a hydraulic pump work with different hydraulic fluids?

It is important to only use hydraulic fluids recommended for your specific pump model. Using the wrong fluid can result in decreased performance and damage to the pump.

3. What are the signs of a failing hydraulic pump?

Common signs include unusual noises, decreased power, leaking fluid, and reduced functionality. If you notice these symptoms, it is crucial to have your pump inspected immediately.

4. Are all hydraulic pumps identical in terms of functionality?

No, hydraulic pumps vary significantly in design and functionality based on their type. Each type is engineered for different applications, pressures, and flow rates.

Contact Us

For more information on our hydraulic pumps or to get expert advice tailored to your specific needs, feel free to contact us today. Let us help you find the right hydraulic solutions to keep your operations running smoothly.